Product Spotlight: Unixil Render Finish Winter Formula

Late autumn and winter is the most dreaded time of the year for many render applicators as temperatures drop and the chance of rain increases.

The unspoken rule of applying render is that it shouldn’t be installed at temperatures lower than 5℃ and increased humidity during the initial setting period. As humidity levels rise, it causes the render take significantly longer to dry and set. This can result in the render washing off and not being applied efficiently.

How to tackle high humidity and ever falling temperatures

JUB has established this as an issue and in order to help plasterers apply a smooth application of render in more restrictive weather conditions, we have manufactured a reinforced winter-grade topcoat.

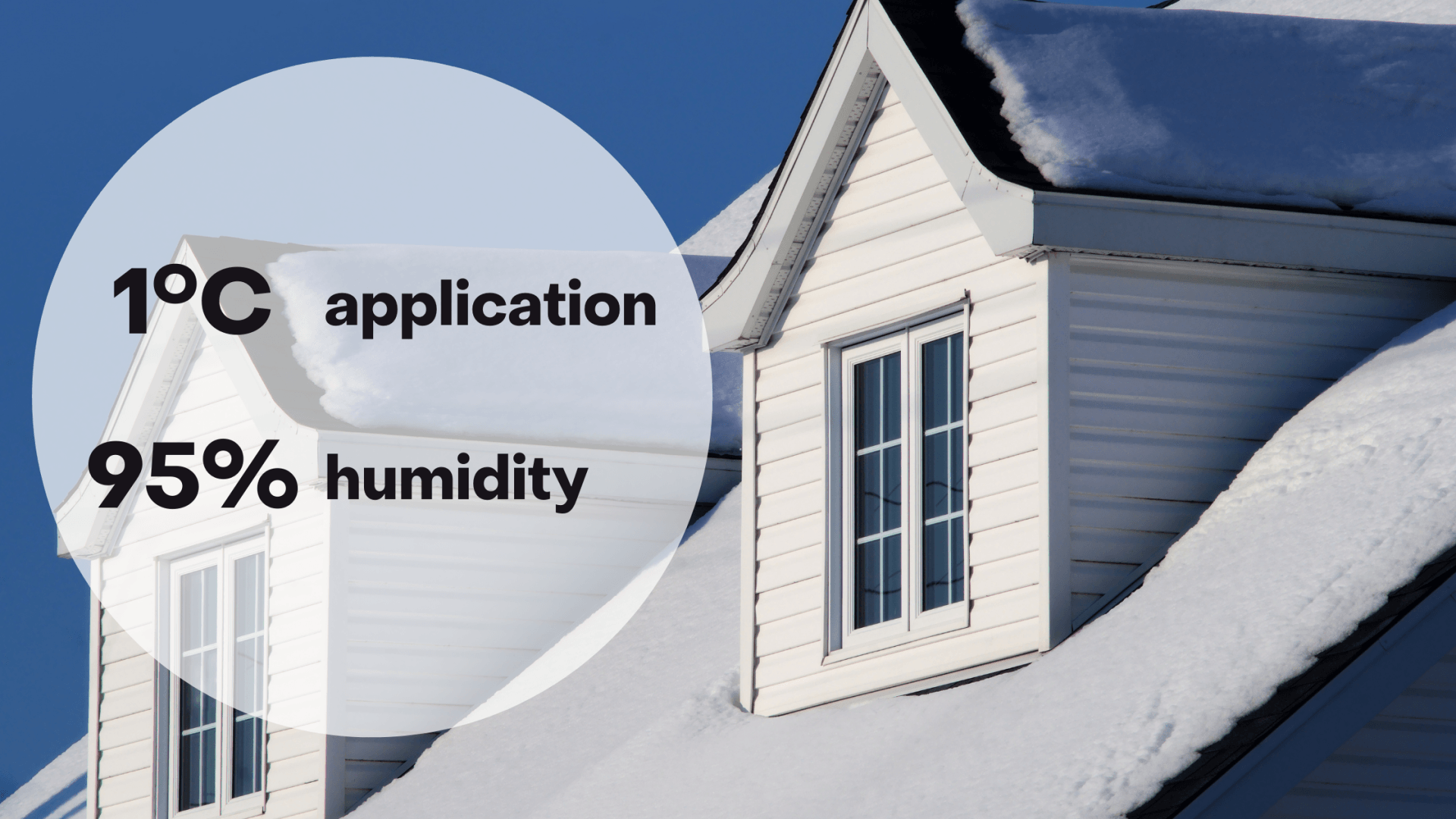

The product can be applied in winter weather conditions where temperatures drop to +1℃ and humidity levels rise to 95%.

As with any of our high-quality render finishes, Unixil Winter Grade comes with many benefits:

- Rain resistant in 24 - 48 hours of application, dependent upon conditions/substrate

- Touch dry within 12 hours

- Easy to apply

- 90 minutes tub time

- Extensive range of colours with over 100 shades to choose from

- The same Siloxane resin quality associated with silicone renders

- Flexible and resistant to shrinkage cracking

- Uniform in colour and texture

- No requirement for any supplementary decorative coatings

- Long-term durability

What is the application process?

To ensure that Unixil Winter Grade is applied efficiently, we have prepared general guidelines to be adhered to.

Prior to the application, the preparation includes applying a base coat, which has to be dry before Unixil is applied. If installed onto a damp basecoat, this will overall prolong the drying time of the render finish.

Important: When mixing, do not add water to the Unixil additive or winter-grade topcoat.

The mixing should be as follows:

Add 1 full 500ml canister of Unixil Additive to one full 25 kg tub of Unixil Winter Grade.- Mix the contents of the tub at a high-speed setting with a drill whisk for at least 2 minutes to ensure that the Additive has fully integrated with the Unixil Winter Grade.

- Trowel on the Unixil Winter Grade as normal and texture with a plastic float as standard.

Pro Tip: You shouldn’t clean the plastic float in water in between texturing but clean with the trowel/spatula as the extra moisture will delay the drying process.

Unixil Winter Grade should be weather resistant within 24-48 hours of application, however, the system will still be curing behind the surface, therefore precautions should be taken not to damage or scratch the render until it has fully hardened.

Levels of humidity above 95% may cause a delay in the drying process.

If you’d like more information on the product or have questions that haven’t been answered by our guide, don’t hesitate to contact our team.

You can call our office on 0116 2879649 or email us at info@jub.org.uk.

Why Silicone Render is the Best Choice for a Property’s Exterior: Benefits, Application & Aesthetics